Lost Foam The Foam that Turns into Gas

Lost foam casting (LFC) is a type of evaporative-pattern casting process similar to investment casting, but it uses foam for the pattern instead of wax. This process takes advantage of the low boiling point of foam, simplifying the investment casting process by eliminating the need to melt the wax out of the Mold.

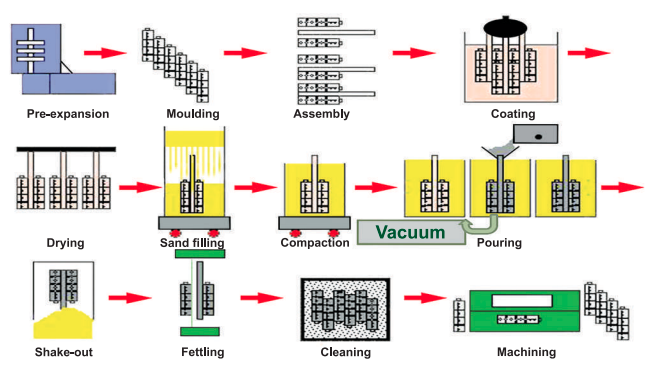

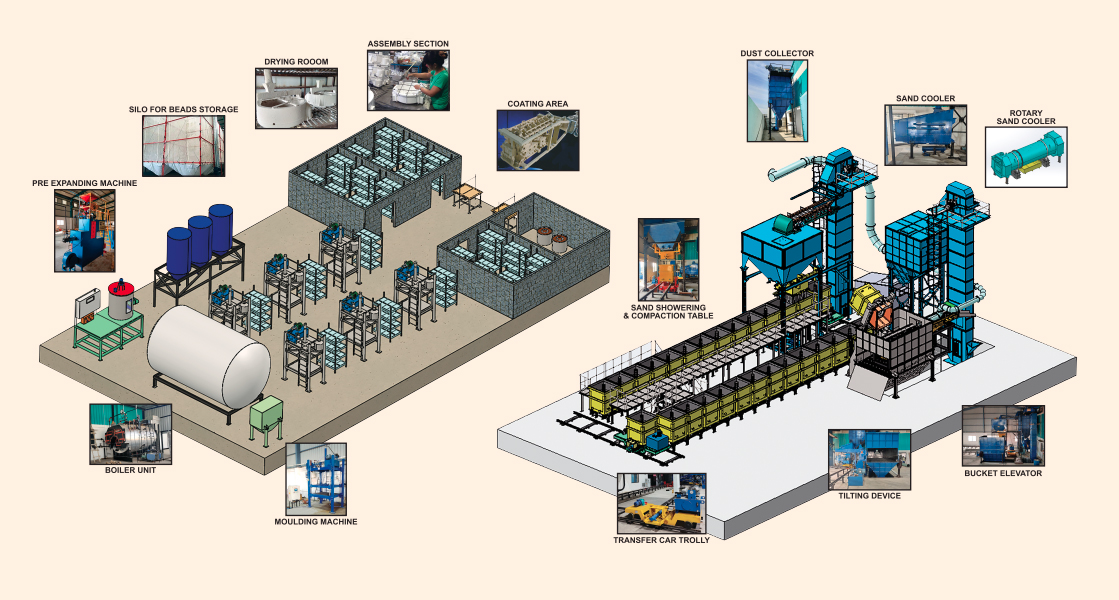

The Casting Process :

The Below Process Consists of 3 Stages Which Assure You Final Finish Casting

- White Part - The making of a polymer foam pattern

- Yellow Part - The Coating of the pattern

- Black Part - With help of compaction table, vaccum system and sand processing plant

"Lost Foam" casting grants the Freedom to create cost effective precision designs, not feasible by conventional methods

- Now a days Indian foundry industry is facing very big problem because of sand scarcity & its disposal.

- Lost foam process is environment friendly processes with more then 95% sand reusable in process.

- Most favorable process for mass production.

- Imparts very good surface finish.

- Can work with less machining allowances.

- Simple process with high automation.

- Weight control on finished product.

- Lost Foam Casting Process is not only fit for castings of simple geometry, but also for multi-part, multi core castings of complex geometry which are hard to make with existing casting technology.

- Negative pressure pouring is more in favor of filling mold and replenishing shrinkage of liquid metals, and also enhances the internal density of casting.

We can also develop the clients' component in LFC with our own Research & Development facility.

We can provide turnkey base solution for LFC plant as well as LFC pattern development and product development.